SAFETY ASSURANCE

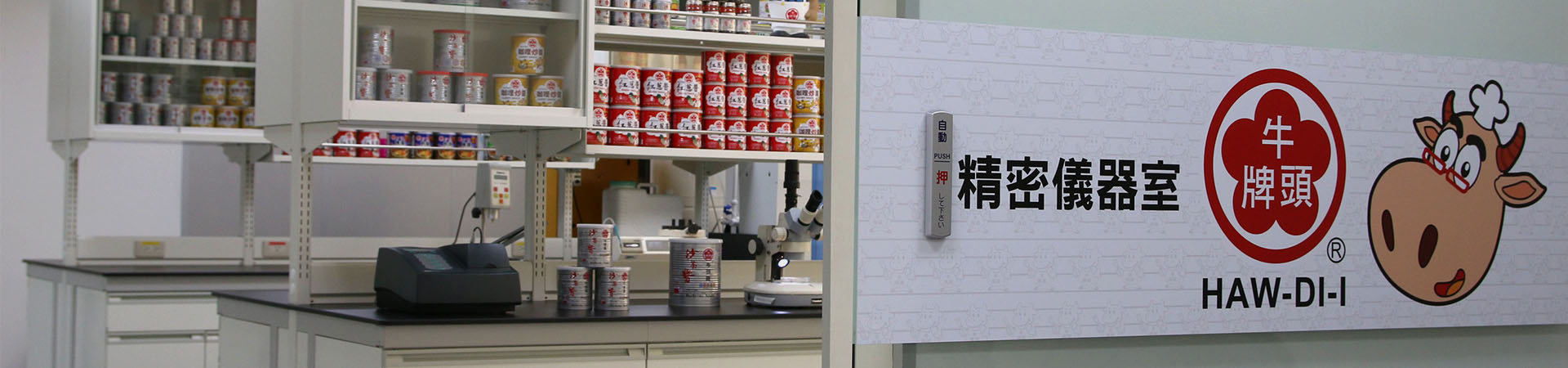

HAW-DI-I insists on quality. HAW-DI-I owns overall production processing, quality control, and hygiene management. We firmly believe that only a safe production procedure can build a tasty and wonderful life. For this reason, we implement food safety analysis, risk management, and food quality certification system and maintenance, as well as control in all aspects. Moreover, the company established the “Precision Instrument Laboratory” in 2015 for study heavy metal and pesticide residues in raw which will be used for the products. These measures assure the raw materials can conform to the standards of the food regulations standard.

Delicacy

Safety

Convenience

Safety study and analysis of raw materials.

The test reports provided by supplier are not only for the result purpose. The test method, process, and original data could also provide lots of information of risk.

Food processing safety analysis and risk assessment

Cooking is only a part of food preparation.The entire process needs to take into consideration of physics, chemistry, micro-organisms, allergens, and other possible risks associated.

Analysis and forecast the new materials, or supplier risks.

- There is more complexity associated with controlling the safety of new sources. We conduct supplier reliability and risk assessment through the possible problems incurred with collecting raw materials worldwide. For example, is there adulteration, environmental pollution, and if the processing adopts chemical practice to upgrade the effect which could not be identified or engages illegal use.

- If the raw materials have a higher risk and there are no reliable suppliers, we will seek for alternative plan and increase the test costs in order to lower risks.

a.Assess the risk level of raw materials, eliminate or lower the risks.

- After assessing or forecasting the risk of existing and new raw materials,we approaches chemical analysis and supplier evaluation to lower possible risks.

- For example, the fishery comes from different oceans,each ocean could be likely contaminated by different heavy metals. Hence, the results of each test can be analyzed for the hazards of sources, thereby the company can control the risk from the certain ocean and avoid the use of fishery with the high-risk source.

b.For supplier risk assessment and management, execute supplier audit according to their risk.

- Classify risk level for supplier and incorporate the risks of raw materials supplied to compile statistics and arrange for annual supplier audit.

c.Review the results of food safety monitoring to discuss measures for agenda with higher risks.

- Conduct a topic discussion on the possible risks incurred from the suppliers, raw materials, and processing.

- For example, spices have pesticide residues issue and only inbound inspection is adopted, there will likely be nonconformance and returning goods, which leads to raw material shortage. Hence, suppliers are required to provide the sample for testing before making the delivery.

d.Assess the applicability of food safety management according to the scientific evidence, data, and experience.

- Based on the historical experience of food safety, evaluate various monitoring project that are superior to regulations.

- Standards higher than the law and regulations should be formulated according to the historic data of tests, which can be used as a requirement of internal risk management.

- Based on the historical data of the inspection, a standard that is superior to the regulations is formulated as an internal risk management requirement.

SQF (Safe Quality Food) certification.

2017: Bullhead Barbecue Sauce, Vegetarian Barbecue Sauce, Barbecue powder were certified.

- Including two categories in food safety and food quality.

- The advantage for consumers: Assure the products purchased by consumers can pass rigorous global standards for food safety and quality.

- SQF certification is a rigorous global plan that has been certified, which is subject to the standards of the Global Food Safety Initiative (GFSI) and meets the majority of monitoring requirements.

- SQF evaluates the company through attention to important food safety and quality elements (such as hazard analysis, risk assessment, and voluntary preventive measures).

- GFSI requires the requirement of food protection, including adulteration and protection.

- Adulteration: For example, honey is often diluted with fructose, which may not harm the human body but is a high-risk item for SQF standard-Insidious raw material or processing is unacceptable.

- Protection: In consideration of the element for protecting food terror attack, for example, the water tower is often targeted for protection, and hence internal and external people have the opportunity to affect the attack for food safety. Therefore,it is necessary to plan to avoid or reduce the possibility of its occurrence.

- Quality: The product manufacturing process must formulate quality control procedures and key points in accordance with food safety analysis procedure. For example, the aroma of dried fish, the spiciness of chili, and the flavor and appearance of the finished product are some of the key quality factors of barbecue sauce.

FSSC 22000 (Food Safety System Certification)

2016: Bullhead Barbecue Sauce and Barbecue powder were certified.

- FSSC is basis of existing ISO standards and provides a framework for effective management of food safety and quality responsibility. It is also fully recognized by the Global Food Safety Initiative (GFSI); Our company’s FSSC 22000 certification also means that we have effective food safety Management system (FSMS), and can meet the requirements of regulatory agencies, food business customers and consumers.

- Although FSSC is also recognized by GFSI, but it is better known by Taiwanese consumers and internationally. After FSSC updating from version 4.1 to 5.0, its requirements are also close to SQF

- The certification systems above, even TQF (GFSI accreditation pending), are based on GFSI, so no matter which certification standard is mentioned above, it will be more and more similar.

- The certification systems under GFSI all emphasize food safety, food quality, food production, and the prevention of food adulteration.

- Although the certification systems are similar, it still depends on the market requirement and habits.

Heavy Metal Analysis:

- Our Food Safety Laboratory is equipped with advanced instruments such as ICP-MS, LC/MS/MS, GC/MS/MS, and Headspace GC/FPD to conduct in-house testing for heavy metals and pesticide residues.

- The laboratory’s heavy metal testing (arsenic, cadmium, mercury, and lead) is TAF certified (Certification No. 3974). The scope and validity of the certification are based on the accredited items and listings announced by TAF.

Pesticide Residue Analysis:

- Pesticide residue testing is conducted in accordance with the testing methods announced and recommended by the Ministry of Health and Welfare, with modifications applied as needed. Currently, residues of 442 types of pesticides can be analyzed.

-

As the first line of defense in raw material control, the food safety laboratory strictly screens high-risk raw materials to prevent any non-compliant ingredients from being mistakenly used in products.